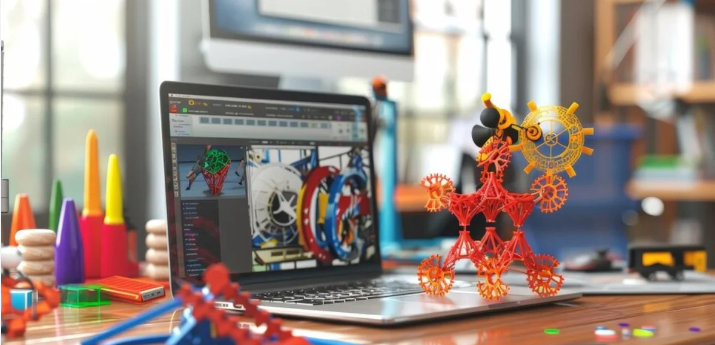

Welcome to 3d659.com blog, your ultimate source for insights into the fascinating world of 3D printing. This innovative technology is transforming industries and changing the way we create, manufacture, and even think about products. In this article, we will explore the future of 3D printing, its applications, advancements, and what lies ahead for this groundbreaking technology.

What is 3D Printing?

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from digital files. This is done by layering materials, such as plastic, metal, or even biological materials, until the desired shape is achieved. Unlike traditional manufacturing methods that often involve cutting away material, 3D printing builds objects from the ground up.

How Does 3D Printing Work?

The 3D printing process involves several steps:

- Designing the Model: First, a digital 3D model is created using computer-aided design (CAD) software. This model serves as the blueprint for the final product.

- Slicing the Model: The digital model is then sliced into thin horizontal layers using slicing software. This process translates the 3D model into instructions that the 3D printer can understand.

- Printing the Object: The 3D printer reads the sliced file and begins to deposit material layer by layer, gradually building up the object.

- Post-Processing: After printing, the object may require finishing touches such as sanding, painting, or assembling multiple parts.

The Current State of 3D Printing

3D printing has come a long way since its inception in the 1980s. Today, it is used in various industries, including:

1. Healthcare

In healthcare, 3D printing is revolutionizing patient care. Medical professionals use it to create customized implants, prosthetics, and even anatomical models for surgical planning. For example, doctors can print a 3D model of a patient’s heart to better understand its structure before performing complex surgeries.

2. Aerospace

The aerospace industry benefits from 3D printing by reducing weight and increasing efficiency. Parts made with 3D printing are often lighter and can be produced more quickly than traditional components. This not only saves time but also contributes to fuel efficiency in aircraft.

3. Automotive

Automotive manufacturers are utilizing 3D printing for prototyping and producing custom parts. This technology allows for faster design iterations and the ability to create complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

4. Fashion and Jewelry

Fashion designers are increasingly adopting 3D printing to create unique pieces of clothing and jewelry. This technology allows for the production of intricate designs that are tailored to individual preferences, offering customers a personalized experience.

Future Trends in 3D Printing

As we look ahead, several exciting trends are emerging in the world of 3D printing:

1. Bioprinting

Bioprinting is the process of creating living tissues and organs using 3D printing technology. Researchers are making significant strides in this area, aiming to produce organs that can be used for transplants. This could potentially solve the shortage of donor organs and save countless lives.

2. Sustainable Materials

The demand for eco-friendly materials is on the rise. Companies are exploring biodegradable and recyclable materials for 3D printing. This shift toward sustainability will not only reduce waste but also promote responsible manufacturing practices.

3. Metal 3D Printing

Metal 3D printing is gaining traction as the technology becomes more accessible and affordable. It allows for the production of complex metal parts, which are essential in industries like aerospace and automotive. As this technology advances, we can expect to see a broader adoption of metal 3D printing.

4. Integration with AI

Artificial intelligence is set to play a significant role in the future of 3D printing. AI can optimize the design process, improve print quality, and even predict maintenance needs for 3D printers. This integration will enhance productivity and efficiency across various industries.

The Benefits of 3D Printing

3D printing offers numerous advantages that make it a game-changer in many fields:

1. Customization

One of the most significant benefits of 3D printing is the ability to customize products. Whether it’s a personalized prosthetic or a unique piece of jewelry, 3D printing allows for tailored solutions that meet individual needs.

2. Cost-Effectiveness

In many cases, 3D printing can be more cost-effective than traditional manufacturing methods. This is especially true for small production runs or complex designs that would require expensive tooling in conventional manufacturing.

3. Reduced Waste

Since 3D printing builds objects layer by layer, it generates significantly less waste compared to subtractive manufacturing methods. This not only saves materials but also minimizes the environmental impact.

4. Faster Prototyping

3D printing enables rapid prototyping, allowing designers and engineers to test their ideas quickly. This accelerates the product development process and allows for faster iterations based on feedback.

Challenges Facing 3D Printing

Despite its many benefits, 3D printing faces several challenges that must be addressed:

1. Material Limitations

While the range of materials available for 3D printing is expanding, there are still limitations. Not all materials are suitable for every application, and some industries require materials with specific properties that may not yet be achievable through 3D printing.

2. Intellectual Property Concerns

The ease of copying digital files raises concerns about intellectual property rights. As 3D printing becomes more widespread, it is crucial to establish clear regulations to protect creators and their designs.

3. Quality Control

Ensuring consistent quality in 3D printed products can be challenging. Variations in printing conditions can lead to defects or inconsistencies in finished items. Ongoing research is needed to develop better quality control measures.

Conclusion

The future of 3D printing is bright, with advancements on the horizon that promise to reshape industries and improve lives. From healthcare to fashion, 3D printing is poised to revolutionize how we create and manufacture products. By embracing this technology, businesses can gain a competitive edge and provide innovative solutions to their customers.

At 3d659.com blog, we are committed to keeping you informed about the latest trends and developments in the world of 3D printing. Stay tuned for more insights and join us on this exciting journey into the future of technology!